![]() With over 25 years of experience and hundreds of satisfied clients worldwide, Fluiteco remains a leader in specialized wastewater filtration treatment equipment.

With over 25 years of experience and hundreds of satisfied clients worldwide, Fluiteco remains a leader in specialized wastewater filtration treatment equipment.

Fluiteco is an engineering company that approaches project management by anticipating, addressing, and responding to project needs. They design, develop, and deliver cost-effective, practical solutions tailored to meet these needs.

They manufacture, deliver and support Screening and Grit Removal systems, Sludge Thickeners, Screw Presses, Disc Filters, mechanical separation packages, and conveyor systems. All their equipment is designed with the client’s specific project requirements in mind.

The exceptional performance of their equipment is guaranteed by high-quality components and their highly skilled production team.

Their team includes experienced assemblers and certified welders, specialized in TIG (Tungsten Inert Gas) welding, a process involving an arc with a tungsten electrode, protected by an inert gas.

Passivation, an electrochemical process that helps prevent corrosion of metals, is applied to enhance the durability of their equipment. After assembly, each machine undergoes rigorous testing and quality control procedures to ensure they deliver the best possible product, meeting the expectations of their global customers.

Products

Screw Conveyors

Hoppers or LBB with Single or Multiple Screws Extractors

Organic Extractor

It separates solid waste, municipal waste and household waste.

The goal is to extract the organic fraction without plastics, aluminium, or other impurities.

Sludge Cleaning Equipment

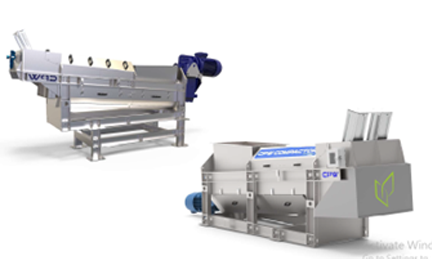

Screw Compactor

Heavy duty screw compactor CPW designed to be installed in every situation where the necessity is to reduce the weight/volume of the waste and to extract liquido/organic fraction.

Sludge Screw Press

INSTALLATIONS:

- Food Industry: wine, cheese, fish, meat.

- Cosmetic industry: pharmaceutical pills.

- Agricultural industry: Composting mixing companies.

- Biogas industry: sludge coming from biodigestor.

- Municipal: WWTP